Four new bathroom floors. A new kitchen ceiling, two new kitchen counters, a new shower head in the master bedroom that would be ideal for anyone shorter than 5’6”. Student plagiarism. Innovation melding 1936 and 2023.

It has been an interesting two months.

I last left off when it appeared we were on track to a rapid end since construction began in April. We didn’t learn enough from the first major part of the renovation: reno=finding tons of problems to solve.

Let me catch you up.

Our last updates I explained the lengthy demo of our master bathroom. Layers and layers of DIY improvements meant that the room had jerry-rigged solutions that added layers and layers of floors and walls and fixtures. I noted earlier that since the house was built in 1936, the only building permits were for a fence and for a new hot-water heater. We know, however, that homeowners after the original residents changed things as major as switching the heat from coal to forced air, and updated rooms more than just decorating. Perhaps permits weren’t required; perhaps the DIY updates weren’t significant enough for a permit.

We did think that when all those layers of previous improvements had been removed that our new bath would be reasonably fast to build, particularly because the core plumbing had already been replaced with the main floor renovation and addition. Ha!

After our crew reframed the walls and floors for the bath and removed all the asbestos (which took weeks) the tiling subcontractors installed the wall tile, which we love:

As a potter, I prefer tile that has variety both in gloss and in depth. This is a challenge for tile setters because it’s more of a puzzle to make the spaces reasonably even and waterproof. This was, however, something we paid in the contract to make work. This tile is floor to ceiling around 3/4 of the bathroom, which is now about 12’ square.

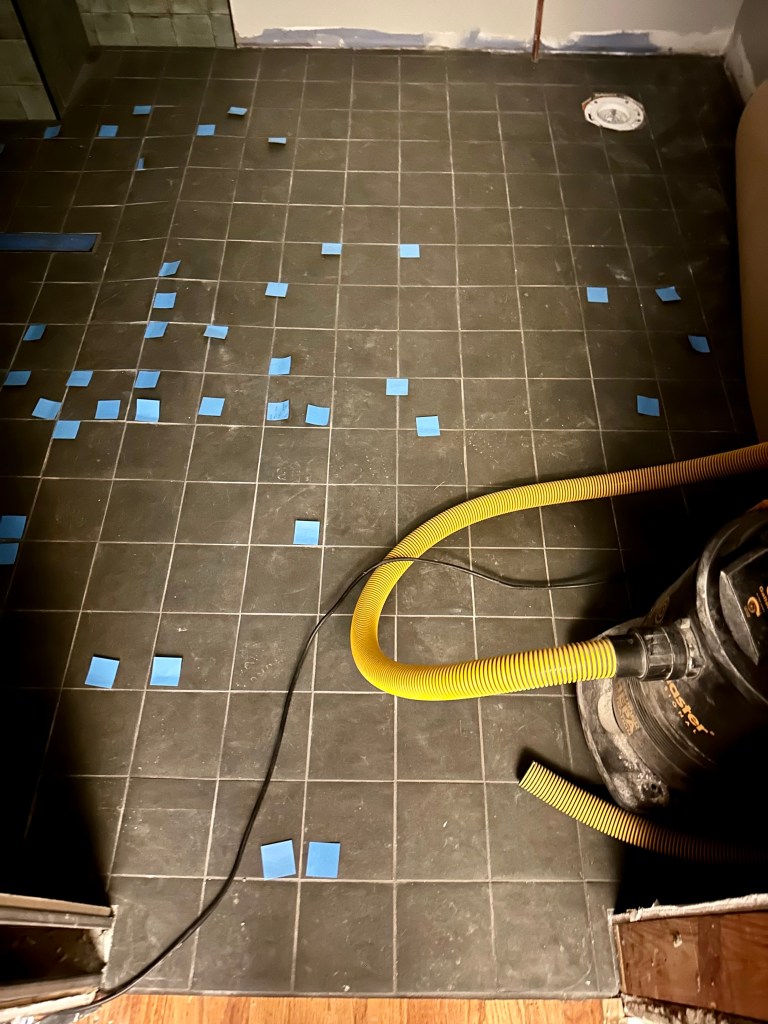

Then they installed the floor tile:

Our new bathing area includes an open (no-step entry) shower with a linear drain and a soaking tub to one side. The mechanics of the linear drain means that in the shower area, the floor angles down very slightly on both sides toward the drain.

The tilers couldn’t get the floor tile right. The first time, tile all across the entire floor included dozens of foot-tearing raised tile edges.

They replaced that floor. Keep in mind that this not cheap tile. They had to rip up the floor and replace it at their own expense.

It still didn’t work:

At this point, everyone was hoping we could live with the bad tiles. THEN, the plumber tested the (way too short, which we didn’t realize at the time) shower and realized that the poorly placed tiles in the shower area (which starts in the dark area on the left of the photo above) meant that the shower would pool water around the floor rather than drain.

Floor three was up (with much swearing) and floor four was installed. We have yet to hear whether the newest floor drains properly, in part …

Because we couldn’t actually walk comfortably in the developing bathroom until the floor was walkable, we did not notice that the one of us who could fit under the shower head was me, barely, at 5’6”. Dan, at 6’2” could only have a stomach wash.

Now sections of the wall must come out to move the shower head to human height.

I will share much more in separate posts, but I want to leave you with something other than the frustration of a major reno: that skilled crews can be amazingly innovative. (I will detail other examples in other posts.)

As I mentioned near the start, our goal in this renovation was to bring our house toward modern features that respected the history of what Glenn and Agda built. A key feature of this includes the Studebaker Rockne faceplates on all the doors in the house. (In case you’re not inclined to click, Glenn, the original homeowner/builder, was a key executive on the Rockne Studebaker car).

The new bathrooms have pocket doors to enable maximum space. That implied that the Rockne faceplate would not be able to stay on the master bathroom door, which would be an anomaly to all the other doors. I asked our main carpenter, J1, if it was in any way possibly to incorporate the faceplate because it was narrow enough not to block the mechanism of the door. I emphasized that if it was difficult, he should abandon the idea.

This dude is a master.

This morning he brought me a narrow pocket-door handle that he though he could shape to fit inside the faceplate to keep the history of the house while enabling the new functionality. Enjoy his expertise (and this baby is vastly more solid than the original.

Leave a comment